Overview |

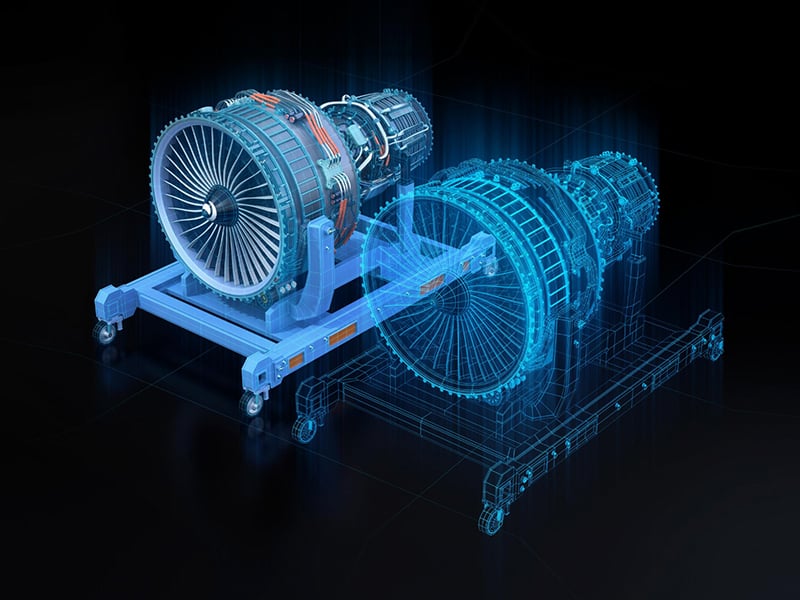

Digital Twins is a digital manifestation of a real-world entity or system. It refers to a virtual model of a process, product, or service. A Digital Twin of assets or products, when combined with digital or virtual representations of facilities and environments, people, businesses and processes, will enable an increasingly transparent and detailed digital replica of the real world.

Digital Twin technology connect the real and virtual world by collecting real-time data from the installed sensors. The collected data is either locally decentralized or centrally stored in a cloud. Subsequently, the data is evaluated and simulated in a virtual copy of the assets. After receiving the information from the simulation, the parameters are applied to real assets or products. With Digital Twins acting as a bridge between the physical and digital world, this convergence of the virtual and real worlds allows for analysis of data and monitoring of systems, processes to proactively identify problems, prevent downtime and potential errors. It helps create a better version of products, and optimizes the performance of real assets.

Digital Twins platform is the next big thing in Industry 4.0 for the development of new processes and products. Driven by the advent of IoT and the Industrial IoT, along with data, analytics, and AI on top, Digital Twins is disrupting the market. NASA was one of the pioneers to use this technology in space exploration missions.

By 2021, half of the large industrial companies will use Digital Twins, resulting in those organizations gaining a 10% improvement in effectiveness' - Gartner

Benefits of Adopting Digital Twins

Digital Twin software benefit organizations in many ways. Predominantly they help envisage, suggest corrective measures, and give predictive analysis and suggestions for optimal product design and performance of futuristic, cutting-edge products.

Innovative product design – Virtual models enable testing before the actual fine-tuned product is made.

Granular level details – A granular view of the feedback received enables continuous betterment and improvement of asset, product, or process.

Predictive maintenance – With the wide use of sensors all around and vast amount of data emitted out of these sensors, Digital Twins helps in the implementation of predictive maintenance. With this, businesses or manufacturing plants do not have to depend on guesswork when the product requires service or maintenance.

Digital Twin software can be used in various industries including but not limited to manufacturing, automotive, construction, utilities, healthcare, space, and defence.

David Cearley, VP and Gartner Fellow at Gartner Research, says “Over time, digital representations of virtually every aspect of our world will be connected dynamically with their real-world counterparts and with one another and infused with AI-based capabilities to enable advanced simulation, operation, and analysis.“

“City planners, digital marketers, healthcare professionals and industrial planners will all benefit from this long-term shift to the integrated Digital Twins world,” he added.

Digital Twins to Enable Remote First Options for Businesses

With Digital Twin technology, businesses can operate Remote-first. By way of remote commissioning, remote operations, monitoring and performing the remote diagnostics of products that are already in the field, Digital Twins help in lowering service costs, and enhance customer satisfaction. Also, they can troubleshoot and rectify equipment in remote locations to reduce incident resolution time. Similarly, when new products are launched, the configuration can be performed remotely by service personnel.

For example, by working with Digital Twins of a wind turbine, the engineers can get all information regarding the operational performance, its condition, rotor temperature, etc. Additionally, they can get predictive maintenance statistics, and corrective measures to be taken, so that they can operate and monitor the wind turbines remotely.

Join our webinar on Digital Twins that will touch upon various aspects of the concept. Some of the topics we will cover in this webinar include:

- Digital Twins concepts, its rising prominence and applications across industries

- Difference between the regular simulator and Digital Twins

- Deep Learning & Digital Twins

- Deep Learning-based Digital Twins in semiconductor manufacturing

- How Remote-first Digital Twins can help businesses save costs and time

- Driving business value and sustainability with Digital Twins

- How AI rewrites the possibilities of Digital Twins

- Live Demo and Use Cases on Digital Twins

Apart from gaining in-depth knowledge of the concept of Digital Twins, webinar participants will get a chance to play and experience the demo on our portal where they can try the Digital Twins of a lithium-ion battery.

Digital Twins and IoT

Gartner expects more than 20 billion sensors and endpoints by 2020, creating an enormous influx of data and insights for businesses.

The extensive use of IoT sensors and Edge computing are the reasons why Digital Twins exists today. Also, as the IoT devices are refined, and as collection of operational data becomes cheaper, Digital Twins scenarios in the future will include smaller and less complicated objects, giving additional benefits to companies.

Applications of Digital Twins Across Industries

Factors driving the unprecedented growth of Digital Twins include the growing adoption of IoT and cloud for the implementation of Digital Twins and the promising prospects of their use in industries such as manufacturing, healthcare, aerospace and defence, supply chain, real state, automotive and transportation.

Manufacturing

Digital Twins can be effective in designing and manufacturing a product. Continuous feedback and ideas coming by way of a virtual twin help give a clear granular view, leading to an emergence of a highly productive manufacturing plant.

Aerospace and Defence

Right from the manufacturing of expensive aircraft – both military and commercial, Digital Twin applications play a crucial role. The virtual twin gives all-clear fine-tuned instructions, pointers on various aircraft parts enabling for a fool-proof production of prototypes.

Automobile

Highly efficient virtual and futuristic vehicles can be brought and tested before the actual manufacturing rollout happens avoiding product design failures, saving time, cost and bringing efficiency, and reaching go-to-market goals for the company.

Healthcare

Digital Twins assist healthcare industry by mimicking critical care components of heart, lungs, etc., and helps in analysing the reports and history of patient health. It becomes easy for the doctors to give the right treatment to their client.

Industrial IoT

Industry 4.0 will see a significant disruption. Digital Twins are increasingly used to check the position of complicated machinery and offer predictive maintenance tracking and predict future operational anomalies.

Retail

Highly appealing customer experience is critical in the retail sector. Digital Twins implementation augment the retail customer experience by creating virtual twins for customers, modelling fashions for them to create an enthralling experience. Better in-store planning and management, security implementation, and energy management are some benefits of implementing Digital Twins in retail.

Construction

A detailed virtual blueprint of real physical construction sites will give a clearer glimpse of potential construction site failure points and design flaws. This, in turn, enables construction companies to build solid foundations leading to significant cost and time saving.

Innominds has an end-to-end capability in Digital Twins technology powered by its IoT, cloud, AI, and ML expertise through which we aim to fulfil the next billion connected devices dream.

Conclusion

As part of digitization and automation of business processes, Digital Twin technology will play a key role, contributing to asset efficiency, better product rollouts, eliminating errors, providing continuous product improvement feedback and predictive maintenance support for various industries.

The Digital Twins technology provides innumerable benefits when combined with AI, IoT, Cloud, advanced analytical tools, and Machine Learning that go beyond improved efficiency and productivity.