“By 2025, nearly two-thirds of digital innovation factories will be prolific software producers with code deployed daily, over 90% of apps cloud-native, 80% of code externally sourced and 1.6 times more developers than today.” - IDC

“We had a great plan, a competitive product, but still, we failed in the market”. Many of us would have come across such a statement when it comes to failed product launches. According to researches, around 50% of “good to go” products do not successfully capture customer’s attention. There could be multiple reasons behind this. Today, we will discuss one of the major attributes that affect the success rates of product launches. That is 'Implementation.'

Implementation is that phase of a project life cycle where the product is rolled out to the end users in a realistic environment. This phase largely determines the success of the project, as the users voice out their experience with the product. There are different implementation techniques that are followed in various industries, some of the popular techniques are

- Phased implementation

- Parallel implementation

- Direct implementation

- Pilot implementation

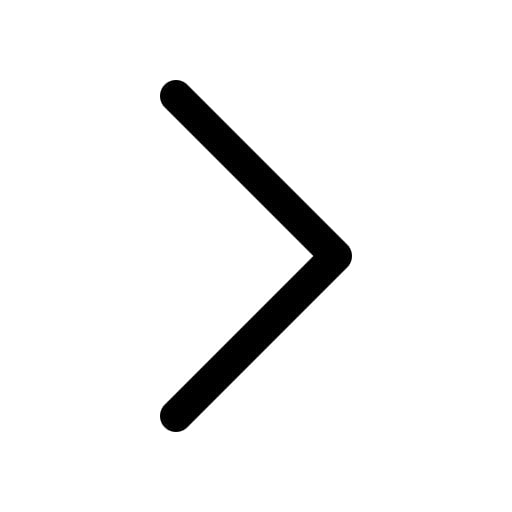

Phased implementation: In order to reduce the complexity of large projects, the requirements are split into several parts. These requirements are then grouped, developed and rolled out in multiple stages to the end users. Consider the online payment applications, in most of them, you will notice that there are services developed to make prepaid/post-paid recharges, bill payments, movie ticket bookings, travel and hotel bookings, etc. These facilities were not implemented in the first version of the application, but in different phases based on the business priority.

Phased implementation: In order to reduce the complexity of large projects, the requirements are split into several parts. These requirements are then grouped, developed and rolled out in multiple stages to the end users. Consider the online payment applications, in most of them, you will notice that there are services developed to make prepaid/post-paid recharges, bill payments, movie ticket bookings, travel and hotel bookings, etc. These facilities were not implemented in the first version of the application, but in different phases based on the business priority.

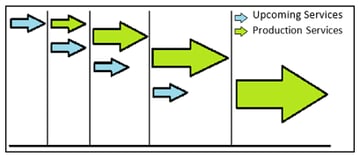

Direct implementation: In this type of implementation, the old systems are replaced with new ones in a single shot. This technique is followed generally when the complexity and risk factors are minimal. Think about the banking applications in your mobile phone, after some specific cut-off dates there will be no support system for making transactions in the older versions of an application unless you install or update to the newer versions of an application.

Direct implementation: In this type of implementation, the old systems are replaced with new ones in a single shot. This technique is followed generally when the complexity and risk factors are minimal. Think about the banking applications in your mobile phone, after some specific cut-off dates there will be no support system for making transactions in the older versions of an application unless you install or update to the newer versions of an application.

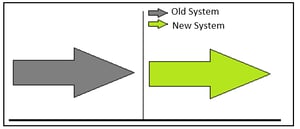

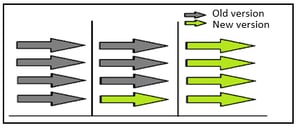

Parallel implementation: Until the newer versions of systems and processes are proved highly reliable, some industries use both the older and newer versions of the software. Once the newly implemented system is stable and ready to support business objectives, the older systems are slowly obliterated. Consider the FASTag system, which enables automatic deduction of toll charges through online process. You will notice in the toll gates, that the previous system of cash counters exists along with the newly implemented digital FASTag counters.

Parallel implementation: Until the newer versions of systems and processes are proved highly reliable, some industries use both the older and newer versions of the software. Once the newly implemented system is stable and ready to support business objectives, the older systems are slowly obliterated. Consider the FASTag system, which enables automatic deduction of toll charges through online process. You will notice in the toll gates, that the previous system of cash counters exists along with the newly implemented digital FASTag counters.

Pilot Implementation: Consider a widespread industry, which needs to roll out a new system across different locations. When the business wants to test the adaptability of this system, one of the ways is to deploy it in a single location and evaluate the real-time outcomes. The outcomes, will then be helpful in making changes and assess the system readiness before implementing it throughout the industry. This kind of technique is called Pilot implementation.

Pilot Implementation: Consider a widespread industry, which needs to roll out a new system across different locations. When the business wants to test the adaptability of this system, one of the ways is to deploy it in a single location and evaluate the real-time outcomes. The outcomes, will then be helpful in making changes and assess the system readiness before implementing it throughout the industry. This kind of technique is called Pilot implementation.

Let’s look at three broad levels of Pilot implementation and understand how the process is used in Automobile industries.

Think about an Automobile manufacturing company, planning to develop new software for its sales and service dealerships/outlets across a country. Now, all these dealerships may not be using the same business workflow. However, there would be some common and standardized procedures followed by all the dealers.

Phase 1: This phase, starts with the development of all the common processes that would be followed across the outlets. The basic idea is not to develop a full-fledged application but to develop an application that can be used at the pilot location without having any business impact. Appropriate software development methodologies are used to build applications. On the other hand, the pilot location has to be finalized in this phase. The major readiness criteria for a pilot dealer include device availability, network connectivity, training the available resources, support system setups, business continuity plans, etc.

Phase 1: This phase, starts with the development of all the common processes that would be followed across the outlets. The basic idea is not to develop a full-fledged application but to develop an application that can be used at the pilot location without having any business impact. Appropriate software development methodologies are used to build applications. On the other hand, the pilot location has to be finalized in this phase. The major readiness criteria for a pilot dealer include device availability, network connectivity, training the available resources, support system setups, business continuity plans, etc.

Phase 2: In the second phase of implementation, the product is rolled out for production at the pilot outlet. This is the time where the end-users are encouraged to provide feedback on the new application. Any changes suggested by the pilot dealer is broadly categorized into process-related changes and application-related changes. For process-related changes, this would be the ideal time for the industry to standardize the workflow, which aligns with the new product well before it is implemented in other locations. On the other hand, application change requests result in enhancing the capabilities of the product, adding more functionalities to the existing application.

Phase 2: In the second phase of implementation, the product is rolled out for production at the pilot outlet. This is the time where the end-users are encouraged to provide feedback on the new application. Any changes suggested by the pilot dealer is broadly categorized into process-related changes and application-related changes. For process-related changes, this would be the ideal time for the industry to standardize the workflow, which aligns with the new product well before it is implemented in other locations. On the other hand, application change requests result in enhancing the capabilities of the product, adding more functionalities to the existing application.

Phase 3: Once the application is enhanced with additional functionalities and tested at the pilot location, it would now be implemented across different locations in the third and final phase. Depending on the outlet readiness, application rollout can be done for all the locations either at the same time or in individual phases. The lessons learned during the pilot roll-out would be helpful in risk mitigation during this final phase. Any change recommended by the dealerships across different locations would be analyzed and customization of the application and/or work-flow can be done for individual outlets.

Phase 3: Once the application is enhanced with additional functionalities and tested at the pilot location, it would now be implemented across different locations in the third and final phase. Depending on the outlet readiness, application rollout can be done for all the locations either at the same time or in individual phases. The lessons learned during the pilot roll-out would be helpful in risk mitigation during this final phase. Any change recommended by the dealerships across different locations would be analyzed and customization of the application and/or work-flow can be done for individual outlets.

Conclusion: Thorough Implementation is all about learning the risk factors much early and stabilizing the product as it rolls out to the end-users. Regardless of what the product is, it is important to think about the implementation in the early stages of product planning. A combination of different implementation techniques may help as well. Remember, poor plans with poor implementation will definitely fail in the market, but sometimes the best of the plans with poor implementation may fail too. While these tips may not ensure success every time, but they will certainly reduce the failure rate and gets you started on the right path. So, Implement well.